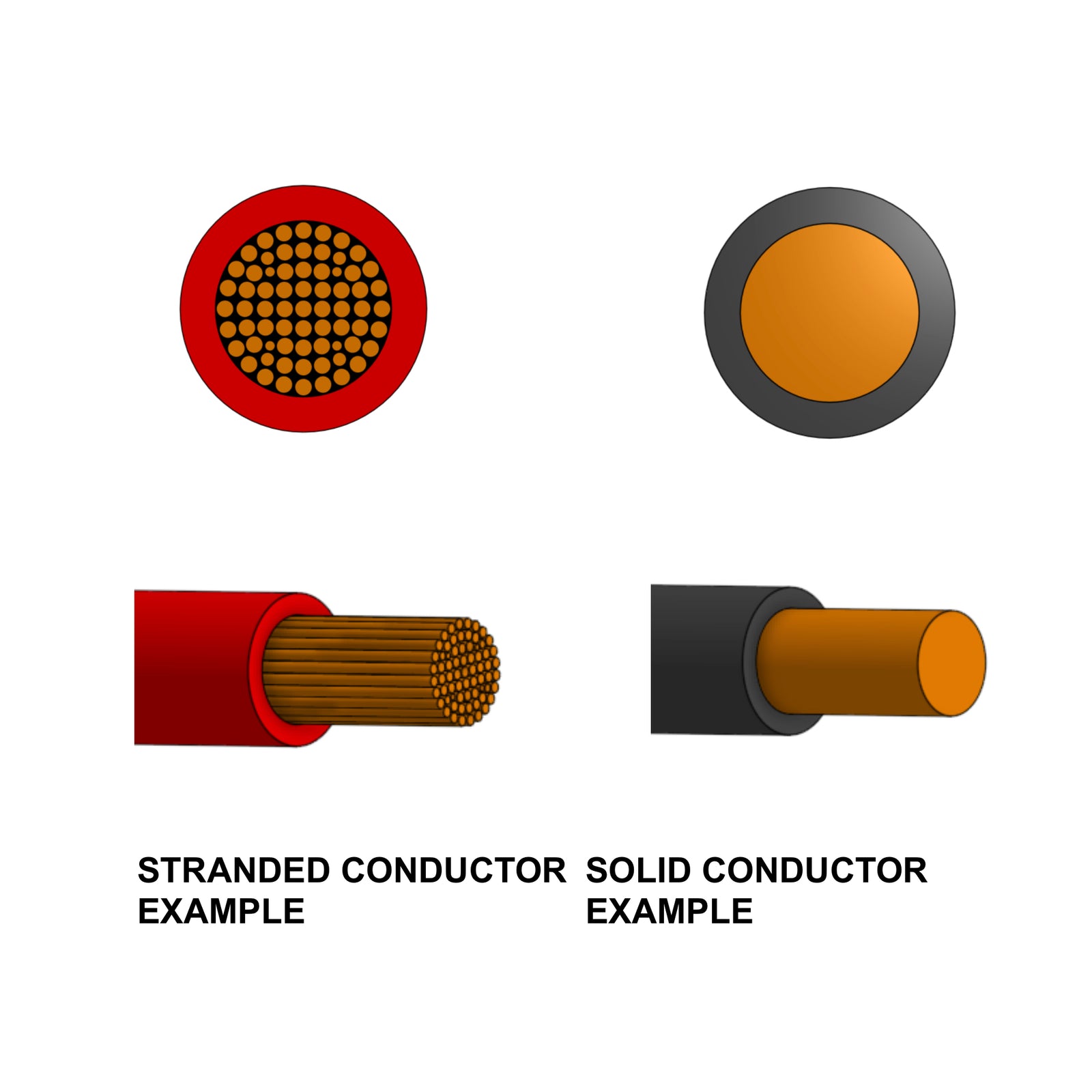

If you're shopping for cable to complete your project, you may come across 2 different types of cables based on conductor type:

- solid

- stranded.

What the difference between them? If few words:

- solid conductor is made out of single string of metal

- stranded conductor consist of multiply wires twisted together.

These two types of conductors have their own unique characteristics and properties that make them suitable for different applications. In this article, we will explore the difference between solid and stranded conductors and their respective advantages and disadvantages.

Solid Conductor

A solid conductor is a single, continuous wire made of a single metal or alloy, such as copper or aluminum. The wire is typically round in shape and is usually used in applications where the wire will not be subject to repeated bending or flexing. The solid conductor has a consistent diameter along its length, which makes it easier to terminate and connect.

Solid conductors are commonly used in residential and commercial electrical wiring, as well as in some industrial applications. They are also used in applications where signal interference is a concern, as they provide a more stable and consistent signal than stranded conductors.

Advantages of Solid Conductors

1.Stability: Solid conductors provide a stable and consistent signal due to their uniform diameter and construction.

2. Lower resistance: Solid conductors have a lower resistance than stranded conductors of the same diameter, which means less power is lost as heat during transmission.

3. Less expensive: Solid conductors are typically less expensive than stranded conductors due to their simpler construction.

4. Easier to terminate: Solid conductors are easier to terminate and connect due to their consistent diameter.

Disadvantages of Solid Conductors

1. Not flexible: Solid conductors are not as flexible as stranded conductors, which can make them more difficult to work with in applications where bending or flexing is required.

2. Breakage: Solid conductors are more prone to breakage than stranded conductors due to their lack of flexibility.

3. Not suitable for some applications: Solid conductors are not suitable for some applications, such as those where vibration or repeated flexing is present.

What is a Stranded Conductor?

A stranded conductor is made up of multiple small wires twisted together to form a single larger wire. The individual wires are typically made of the same metal or alloy as solid conductors, such as copper or aluminum, and are usually coated in a layer of insulation.

Stranded conductors are commonly used in applications where flexibility is required, such as in automotive and aerospace applications, as well as in some industrial and residential applications.

Advantages of Stranded Conductors

1. Flexibility: Stranded conductors are much more flexible than solid conductors, which makes them suitable for applications where bending or flexing is required.

2. Reduced breakage: Stranded conductors are less prone to breakage than solid conductors due to their increased flexibility.

3. Suitable for vibration: Stranded conductors are suitable for applications where vibration is present, as they can absorb and dissipate some of the energy caused by vibration.

4. Suitable for high-current applications: Stranded conductors are suitable for high-current applications due to their increased surface area, which allows for better heat dissipation.

Disadvantages of Stranded Conductors

1. Higher resistance: Stranded conductors have a higher resistance than solid conductors of the same diameter, which means more power is lost as heat during transmission.

2. More expensive: Stranded conductors are typically more expensive than solid conductors due to their more complex construction.

3. More difficult to terminate: Stranded conductors are more difficult to terminate and connect due to their varying diameter.

Summary

In conclusion, the choice between solid and stranded conductors depends on the specific application requirements. Solid conductors are typically used in applications where flexibility and vibration are not major concerns, and where a stable and consistent signal is needed. They are also less expensive and easier to terminate than stranded conductors.

Fins the wide range of the 12V Single Automotive Cable

On the other hand, stranded conductors are suitable for applications where flexibility and vibration resistance are important, and where a higher current carrying capacity is needed. They are also less prone to breakage and have a larger surface area, allowing for better heat dissipation.

It is important to consider the specific application requirements and consult with a professional to determine which type of conductor is the most suitable for the job. Additionally, it is important to ensure that the conductor meets the necessary safety and regulatory standards for the specific application.

In summary, solid conductors are suitable for applications where stability and consistency are required, and where flexibility and vibration resistance are not major concerns. Stranded conductors are suitable for applications where flexibility and vibration resistance are important, and where a higher current carrying capacity is needed. Both types of conductors have their own unique advantages and disadvantages, and it is important to choose the appropriate one for the specific application to ensure safety and optimal performance.